|

|

| |

| SAP PLM in ERP |

| |

SAP PLM has since long been an integral part of SAP’s integrated ERP Suite. Grown from its roots in managing master data, today it supports a wide variety of processes and thus forms the heart of an integrated product development process. It’s capabilities range from managing product data like documents, BOMs and recipes to managing engineering change processes and it also offers a comprehensive project management solution.

The differentiating strength of the PLM solution within ERP roots in its deep integration with other corporate key functions. The PLM solution e.g. integrates product engineering with Sales and Manufacturing, Product Management with Financials and Human Capital Management.

The SAP PLM functionality within ERP offers support for a wide range of industries, including both discrete and process manufacturing industries, consumer products as well as asset intense industries. Although SAP PLM is an integral part of the ERP suite, the solution can be deployed as a separate PLM System without losing the advantages of a deep integration into the ERP system.

|

| |

| |

|

| |

| Business Challenge |

| |

Today’s consumers across different industries demand ever new and innovative products delivered to the market in short cycles at a competitive price. Manufacturers are urged to keep development cycles short and contain the cost of developing new products. On the other hand side, product complexity is rising and products are being developed in networks that span across company borders. The focus therefore needs to be on development efficiency as well as on product compliance. Resources – both financial and labour – need to be spent wisely while protecting corporate Intellectual property.

|

| |

| Solution |

| |

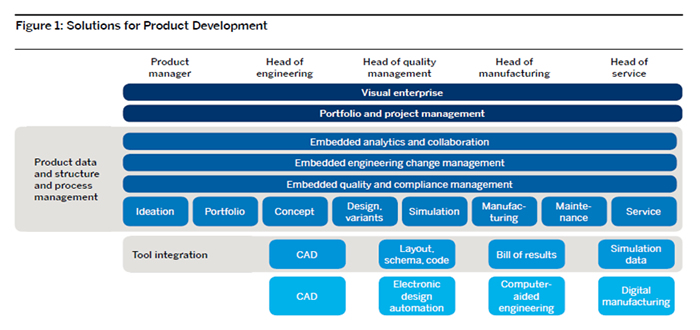

SAP PLM in ERP offers a whole set of solutions that help address the below mentioned issues:

SAP PLM in ERP offers a whole set of solutions that help address the below mentioned issues:

Document Management: Helps to manage the structured and unstructured information and content electronically and across your business process within ERP.

Authoring Tools Integration and Visualization: Integrate your CAD tools and make the CAD content accessible as 3D models for non-CAD Users.

Material Management: Keep one consistent and comprehensive record of your material information throughout the Product lifecycle created in R&D which is enriched later and used in manufacturing, purchasing and other functions.

Bill of Material: Manage Bills of Material for both Engineering and Manufacturing to provide an always up-to-date view of the product.

Product Structure Management: Manage your highly variant product structures from an early stage until hand-over to production stage.

Recipes: Manage the composition and process to create process manufactured goods. Create labels.

Routings: Create and store the sequence and details of your manufacturing process as basis for planning and scheduling.

Change management: Manage both the process to initiate and discuss a change as well as the process to carry out the change.

Classification: Characteristics and classes across various objects helps to enrich the product information with properties to speed up search and foster re-use of components.

Variant Configuration: Modularize your product in engineering in the way you want to sell it, to foster re-use of components.

Product Structure Synchronization: Transfer your Engineering BOMs or Recipes to Manufacturing BOMs and reconcile them with system support anytime you get and update BOM version from your R&D

Access Control Management and cFolders: Allows to collaborate on product information in the development process with internals and externals over the internet while protecting your IP.

Project System: Manage projects of all sizes including their resources and financials

Data Distribution: Distribute product information from one system to another, allowing a high degree of freedom in setting up your system landscape.

Business Context viewer: Make use of all the information in the system landscape and push it right to the users where it is needed and when it is needed.

|

| |

| Business Benefits |

| |

The SAP PLM solution in ERP allows you to manage all Product information and the processes around their creation in one single, integrated solution. It helps you to stay ahead of the competition by streamlining your development processes, reducing innovation cycle times thus lowering development cost while delivering more transparent and reliable results.

For any enquiries contact us info@edstechnologies.com

|

|

EDS Technologies Pvt Ltd.

Bangalore | Chennai | Coimbatore | Hyderabad | Kochi | Mumbai | Pune | Ahmedabad | Gurgaon | Noida | Kolkata

Email : info@edstechnologies.com | Toll Free: 1800 425 3378

www.edstechnologies.com

Find us on

|