|

| 2nd November, 2015 |

| |

| Plastic Flow Simulation- Not an Afterthought; But Necessity

|

| |

|

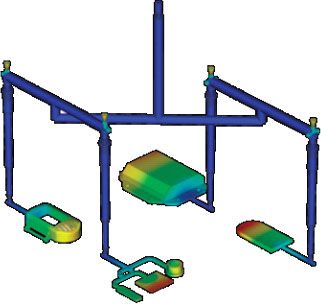

The most branded and trusted product for plastic flow simulation for nearly three decades has been Autodesk® Moldflow®. Autodesk® Moldflow® is a product under Autodesk’s portfolio of simulation products which includes Autodesk® Moldflow®, Autodesk® CFD, Autodesk® Nastran® and Autodesk® Helius PFA & Composites. It has been helping users for decades to compress their product development cycle and deliver products within timeframes and in line with end customers’ high quality standard. With Autodesk® Moldflow®, designers, engineers, and analysts have improved plastic part designs, injection mold designs and manufacturing processes. It is in line with today’s corporate vision of quality standards, delivery timelines and cost effective injection molded products. Through the software, users have answered critical design criteria’s of fit, form and function. “Right First time” is no more the buzz word. What is demanded now is “Right First time, every time with minimum time”. The most branded and trusted product for plastic flow simulation for nearly three decades has been Autodesk® Moldflow®. Autodesk® Moldflow® is a product under Autodesk’s portfolio of simulation products which includes Autodesk® Moldflow®, Autodesk® CFD, Autodesk® Nastran® and Autodesk® Helius PFA & Composites. It has been helping users for decades to compress their product development cycle and deliver products within timeframes and in line with end customers’ high quality standard. With Autodesk® Moldflow®, designers, engineers, and analysts have improved plastic part designs, injection mold designs and manufacturing processes. It is in line with today’s corporate vision of quality standards, delivery timelines and cost effective injection molded products. Through the software, users have answered critical design criteria’s of fit, form and function. “Right First time” is no more the buzz word. What is demanded now is “Right First time, every time with minimum time”. |

| |

With Injection Molding technology heading towards a new era wherein plastic experts are trying to give more than their customer’s expectation, the deliverables through Autodesk® Moldflow® opens up a basket of options. Plastic manufacturing companies are finding it immensely challenging to live up to customer’s quality standards while ensuring heavy cut down on costs and more so ever they have heavy competition to deal with. They are looking at options of ‘metal to plastic’ conversion which does not only save cost, but also increases fuel efficiencies which is another upcoming global challenge from the automotive industry perspective. Manufacturers are replacing metals with composites or fiber filled plastics which physically have metal like mechanical properties that can sustain loads, impacts but these parts have serious manufacturing issues when it comes to dimensional stability and aesthetic appeal. Added to this there are several global and local plastic raw material manufacturers with huge number of grades available in commercial market and this adds more complexity and confusion for the manufacturer’s on decision making. This is where Plastic Flow Simulation Software such as Autodesk® Moldflow® plays a critical role in manufacturers day to day activities of product development. Plastic manufacturers believe that the software is a boon for their new product development which is absolutely required to give one a cutting edge over competition. With Injection Molding technology heading towards a new era wherein plastic experts are trying to give more than their customer’s expectation, the deliverables through Autodesk® Moldflow® opens up a basket of options. Plastic manufacturing companies are finding it immensely challenging to live up to customer’s quality standards while ensuring heavy cut down on costs and more so ever they have heavy competition to deal with. They are looking at options of ‘metal to plastic’ conversion which does not only save cost, but also increases fuel efficiencies which is another upcoming global challenge from the automotive industry perspective. Manufacturers are replacing metals with composites or fiber filled plastics which physically have metal like mechanical properties that can sustain loads, impacts but these parts have serious manufacturing issues when it comes to dimensional stability and aesthetic appeal. Added to this there are several global and local plastic raw material manufacturers with huge number of grades available in commercial market and this adds more complexity and confusion for the manufacturer’s on decision making. This is where Plastic Flow Simulation Software such as Autodesk® Moldflow® plays a critical role in manufacturers day to day activities of product development. Plastic manufacturers believe that the software is a boon for their new product development which is absolutely required to give one a cutting edge over competition.

|

| |

| |

Moreover, in the recent years the developments of software have been moving hand to hand with the recent development of new technologies in the plastic industries. Processes like Microcellular injection molding, Induction heating, Conformal cooling, Mu-Cell Technology, Bi-Injection and Co-injection etc., are the recent developments wherein plastic manufacturers are moving onto new horizons by establishing these processes. Autodesk® Moldflow® development team does understand the fast moving trends of the industry and have taking strides forward to implement these technologies in the software too. Autodesk® Moldflow® has an exhaustive material library which contains materials from global polymer manufacturers and their several grades. Most of the grades are tested in the ‘State of Art’ either of the 2 Plastics Laboratory located in Australia and USA. Users who have experienced the software believe that such a library is unique in the industry and enriches their exploration to no limits wherein they can virtually test and validate materials merely with a workstation. Major Tier I’s are also going to an extent wherein they are reverse engineering their warped models through Moldflow to finally end up with parts with correct dimensions. Moreover, in the recent years the developments of software have been moving hand to hand with the recent development of new technologies in the plastic industries. Processes like Microcellular injection molding, Induction heating, Conformal cooling, Mu-Cell Technology, Bi-Injection and Co-injection etc., are the recent developments wherein plastic manufacturers are moving onto new horizons by establishing these processes. Autodesk® Moldflow® development team does understand the fast moving trends of the industry and have taking strides forward to implement these technologies in the software too. Autodesk® Moldflow® has an exhaustive material library which contains materials from global polymer manufacturers and their several grades. Most of the grades are tested in the ‘State of Art’ either of the 2 Plastics Laboratory located in Australia and USA. Users who have experienced the software believe that such a library is unique in the industry and enriches their exploration to no limits wherein they can virtually test and validate materials merely with a workstation. Major Tier I’s are also going to an extent wherein they are reverse engineering their warped models through Moldflow to finally end up with parts with correct dimensions. |

| |

|

|

| |

| About EDS Technologies Pvt.Ltd. |

| |

EDS Technologies Pvt. Ltd. (EDST), established in 1995, is the largest PLM and Real-Time Visual Simulation solutions provider in India. EDST partnering with global leaders including DassaultSystemes, SAP, Autodesk, Presagis and VT-MAK provides CAD/ CAM/ CAE/ PLM/ ERP and 3D Visual simulation solutions, Training and on-site resources bringing in the most complete solution for any size and type of industry.

EDST's differentiation is its domain expertise, consultative approach and hands-on understanding of customer requirements required to drive successful implementations with world class training and technical support. With nearly two decades of experience, EDST has the largest customer base in the Indian market with more than 1000 customers from aerospace, automotive & supply chains, industrial machinery, high-tech and electronics, railways, infrastructure, consumer packaged goods, engineering service providers, defense, research and education sectors. |

| |

| For more information log on to www.edstechnologies.com |

| |

|

| |

|